PRINT DATA UPLOAD

Simply drag the files or folders with your print data into the upload field, or select the folder with your print data.

Do you need help uploading your print data?

CREATE PRINT DATA?

To be able to create optimal print data for our products, we have compiled some tips for you.

Bleed

The bleed refers to the area outside the trim that is subsequently sewn with the rubber lip after printing. To avoid white flashes, it should amount to 1% per side length all around. For frame sizes under 2000 mm, a bleed of 20 mm is needed. Whether it's a photo or graphic design: The background of the print file should fill the entire bleed area. For a frame size of 1000 x 3000 mm, the print data size is thus 1040 x 3060 mm. The folding, cutting, or registration marks commonly used in layout programs within the data format must not be activated.

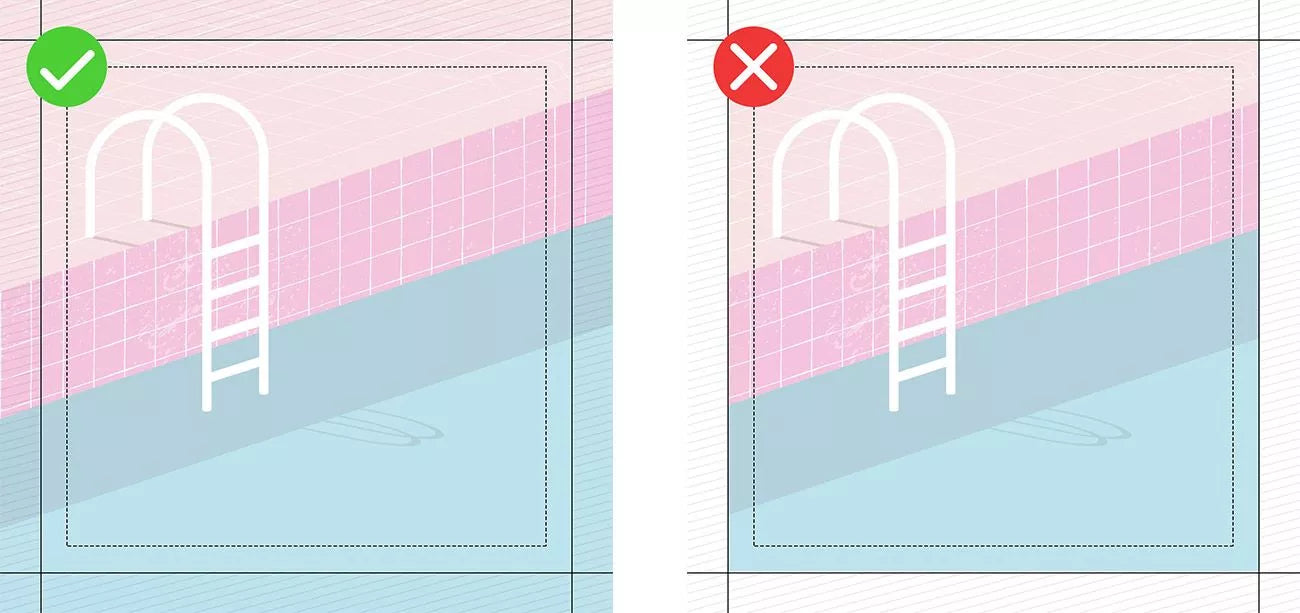

Safety Zone

The safety zone is located within the trim and describes the area within which texts, important parts of a photo, logos, or other design elements should be placed. The area outside this zone is a maximum of 20 mm. To ensure that all details remain visible in the final format, all important elements of the design should be within the safety zone. The printed textiles have a high stretch content, so there is a particular risk with large motifs that elements at the edge may disappear into the frame with the rubber lip. Contours and outlines of entire motifs are not recommended. Due to the flexibility in the textile, they can easily turn out uneven or off-center.

CMYK

A process color is created by printing certain colors at different screen angles. In the traditional four-color printing that we use, these colors are Cyan, Magenta, Yellow, and Black. Therefore, the print data provided should be exclusively in pure CMYK. Using Lab or RGB color spaces can lead to color deviations.

Trim

The final size of the textile print is referred to as the trim. It is the area of the motif that will be backlit in the frame later and is identical to the ordered frame dimensions.

dpi

The dpi (dots per inch) number indicates the dot density in image reproduction and is thus one of the quality aspects in printing. The abbreviation stands for dots per inch. The finer the dot density, the better these print dots blend for the human eye, and the better the print result is perceived. Since we print on a textured surface (fabric), we require a lower resolution (dot density) of 72 dpi, which is less than, for example, paper printing (300 dpi).